Refrigerated Air Dryer Basics

Refrigerated Air Dryers can help you solve the problem of harmful moisture in your compressed air system. Excess moisture in your system can harm equipment and ruin processes or product, costing you time and money. This method of drying is very popular as it produces dew points, which are adequate for most applications using well proven technologies that encounter few problems if properly sized, installed and maintained.

Refrigerated Air Dryer FAQ’s

Q. How does Water get in your compressed air?

A. Compressor Inlet. Water vapor (humidity moisture) enters the air system through the air compressor inlet air filter. The air compressor sucks in approximately 7 cubic feet of atmospheric air at 0 psig, and that volume of air is compressed into 1 cubic feet of air at 100 psig. The water vapor (humidity moisture) that was in the 7 cubic feet of atmospheric air is now compressed into 1 cubic feet of compressed air. There are 3 forms of water in compressed air: 1. Liquid water 2. Aerosol (mist) 3. Vapor (gas) Liquid water is easily removed by general purpose filters. They remove 98% of the liquid water and less than 10% water mist & 0% vapor. Water in Aerosol or Vapor form requires the use of a Compressed Air Dryer. For every 50°F drop in compressed air temperature, the moisture holding capacity of air is reduced by 50%. Drying prevents liquid water forming downstream where it can contaminate or damage the system causing operating problems, costly maintenance, and repairs.

How A Refrigerated Air Dryer Works

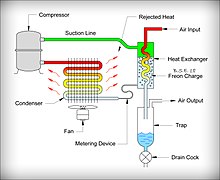

COMPRESSED AIR CIRCUIT

• The refrigerated air dryer cools the incoming compressed air first in an airtoair heat exchanger where the outgoing cool dry air pre cools the hot incoming air and condenses some moisture out.

• Then the incoming air enters an air to refrigerant heat exchanger where the air is cooled to 38⁰F by the liquid refrigerant.

• This process causes the moisture to condense into liquid water and it is drained away.

• The outgoing air then enters the airtoair heat exchanger and is warmed up to keep the outside of the pipes from sweating.

REFRIGERATION CIRCUIT

• The refrigeration compressor pumps hot high pressure gas refrigerant (Freon) into the condenser that transfers the heat from the refrigerant gas to the ambient air as the gas condenses into a liquid.

• The liquid refrigerant (Freon) is then metered to a cold low pressure where it enters the air to refrigerant heat exchanger and the heat from the hot compressed air is absorbed into the cold refrigerant (Freon).

• The refrigeration compressor then sucks low pressure hot gas refrigerant (Freon) into the refrigeration compressor and the cycle starts over again.

What is “PRESSURE DEW POINT”?

Pressure Dew Point : For a given pressure, the temperature at which water VAPOR will begin to condense INTO liquid water.

What pressure dew point do I need?

First here’s some information to help you understand pressure dew point: The lowest pressure dew point class for a refrigerated dryer is Class 4. Class 4 delivers a pressure dew point of +38°F. Refrigerated dryers should not operate below the Class 4 range because the water vapor will freeze in the dryer. The highest pressure dew point for a refrigerated dryer is Class 6. Class 6 delivers a pressure dew point of +50°F. The highest practical pressure dew point because higher pressure dew point causes condensation in downstream piping.

Ways to Determine Pressure Dew Point:

1. Ask the Manufacturer what the pressure dew point (PDP) requirements are for your equipment.

2. You can CALCULATE the PRESSURE DEW POINT TEMPERATURE you need.

Here’s how:

1. Determine the lowest ambient temperature your compressed air piping system will be exposed to. Check the location of airlines throughout air conditioned or unheated areas, underground or between buildings. (For example, your compressor and piping is inside your facility and the lowest air temperature it would ever be exposed to is 58⁰F.)

2. Now you need to take that temperature number and lower it by 20⁰F. (For example, your 58⁰F lowest ambient temperature 20⁰F = (38⁰F PDP NEEDED) This will give the PRESSURE DEW POINT TEMPERATURE needed to prevent liquid water forming downstream. Determining the PRESSURE DEW POINT TEMPERATURE will help you determine the “dew point class” of the dryer you need.

These “classifications” are industry standards for compressed air dryers as established by the ISO (International Organization for Standardization).

ISO 8573.1 AIR QUALITY CLASSES of PRESSURE DEW POINTS THAT APPLY TO REFRIGERATED AIR DRYERS:

Class 4 maximum pressure dew point +38⁰F

Class 5 maximum pressure dew point +45⁰F

Class 6 maximum pressure dew point +50⁰F The lower the dew point, the dryer the air.

How to Size a refrigerated air dryer?

Here are some FACTORS TO CONSIDER WHEN DETERMINING your DRYER SIZE:

Standard Rated Conditions Are:

• 100⁰F Dryer Inlet Air Temperature

• 100⁰F Ambient Temperature

• 100 PSIG Inlet Pressure

• 38⁰F Pressure Dew Point Temperature

• 40⁰F Minimum Ambient Air Temperature

Note: Any deviation from standard conditions requires air dryer size adjustments. Use Correction Factor Tables to help determine dryer size.

• Pressure Dew Point needed (PDP)

• Volume of compressed air (SCFM)

• Maximum compressed air dryer inlet temperature (°F)

• Maximum ambient temperature (°F)

• Maximum compressed air pressure (PSIG)

• Maximum allowable dryer pressure drop (PSIG) To size dryer capacity for conditions other than the Standard Rated Conditions, use the Correction Factors (Multipliers) from Table 1, 2 and 3. Example: You’ve determined you need to treat 500 CFM (125 HP) of Compressed Air for your business. You are considering a dryer, which treats up to 500 CFM. You need your dryer to run under the following conditions different from the Standard Rated Conditions (which may include higher temperatures due to hot days of summer):

• 120⁰F Inlet Air Temperature (Standard =100⁰F Inlet Air Temperature)

• 125 Psig Inlet Air Pressure (Standard =100⁰Psig Inlet Pressure)

• 110⁰F Ambient Air Temperature (Standard =100⁰F Ambient Temperature)

• 38⁰F Dew Point Temperature (Standard =38⁰F Dew Point Temperature) The Model you’ve chosen can treat up to 500 CFM of compressed air under Standard Rated Conditions (listed above). When conditions change like surrounding temperatures on hot summer days, these conditions affect how much compressed air your dryer can treat. (it could be more or less CFM). If conditions vary from Standard Rated Conditions, your air dryer may not meet performance standards.

Use the tables shown to determine the correct size of dryer you need under your specific conditions.

Look @ Table 1 Find Where Inlet (125 Psig) Pressure & Inlet Temperature (120⁰F) Intersect. This number is Your Correction Factor (.74) Multiplier.

Multiply (500) X (.74) = 370 CFM Corrected.

TABLE 1 – Correction Factors for Inlet Air Temperature

| Inlet Air Pressue (PSIG) | 80°F | 90°F | 100°F | 110°F | 120°F |

| 50 | 1.35 | 1.05 | 0.84 | 0.69 | 0.596 |

| 80 | 1.50 | 1.17 | .095 | .079 | .066 |

| 100 | 1.55 | 1.23 | 1.00 | 0.82 | 0.70 |

| 125 | 1.63 | 1.31 | 1.07 | 0.91 | 0.74 |

| 150 | 1.70 | 1.37 | 1.03 | 0.95 | 0.80 |

| 175 | 1.75 | 1.42 | 1.18 | 0.99 | 0.84 |

| 200 | 1.80 | 1.47 | 1.22 | 1.03 | 0.89 |

Look @ Table 2 Determine the Maximum Ambient Temperature surrounding the Dryer. For our example, we will use 110⁰F (for a hot summer day). The table tells you your Correction Factor is (.94). Use the corrected CFM number determined by Table 1 (370) and multiply it by the Table 2 correction factor for 110⁰F (.94).

Dryer Corrected CFM (370) X (.94) =348 CFM Corrected.

TABLE 2 – Correction Factors for Ambient* Temperature (*Surrounding air temperature)

| AMBIENT AIR TEMPERATURE | 80°F | 90°F | 100°F | 110°F |

| Multiplier | 1.12 | 1.06 | 1.00 | .094 |

Look @ Table 3 What dew point do you need to prevent water from forming down stream in your piping? (38⁰F) The Dryer Correction Factor for 38⁰F is 1. Multiply that number times the Dyer Corrected CFM determined from Table 3.

(1) X 348 CFM = 348 CFM Corrected.

TABLE 3 – Correction Factors for Compressed Air Dew Point Temperature

| COMPRESSED AIR DEW POINT TEMPERATURE | 38°F | 40°F | 45°F | 50°F |

| Multiplier | 1.0 | 1.1 | 1.2 | 1.3 |

CONCLUSION FROM USING THE CORRECTION TABLES: USING THE ABOVE TABLES, we can conclude that a 500 CFM Dryer working under these NON-Standard conditions is only able to treat 348 CFM and is too small for our needs. THE DRYER NEEDED IS a 750+ CFM.

CORRECTION FACTOR TABLES Correction Factors (Multipliers) to Adjust Dryer Flow Capacity Other Than Standard Rated Conditions Are:

DRYER CORRECTED CFM = 521 CFM.